Quality and safety

Count on us to deliver the botanicals you need -

in the quality you expect

Our products are delicate and natural creations. As participants in the value chain, we carry a special responsibility towards our customers. We don’t take this responsibility lightly and are completely invested in the quality and safety of our products.

We stand by our protocols and integrated management system while continuing to pursue certifications from regulators and external organizations. This ensures consistent compliance with all requirements and enables us to identify and minimize risks as early as possible in the raw material sourcing stage.

>80

Our botanicals are sourced from more than 80 countries around the world.

>200

Our portfolio contains over 200 botanicals.

>40.000 t

Our more than 40,000 ton-storage capacity protects us against crop failures.

>85.000 t

We process over 85,000 tons of raw materials per year.

Certifications

Product seals for your customers

End consumers are increasingly curious to learn where and how the ingredients of the products they use have been sourced. As a result, demand for certified products is on the rise.

Examples from our portfolio:

- EU-Organic-Label DE-ÖKO-006

- Fair-for-Life

- Fairtrade

- FairWild

- Rainforest Alliance

- UTZ

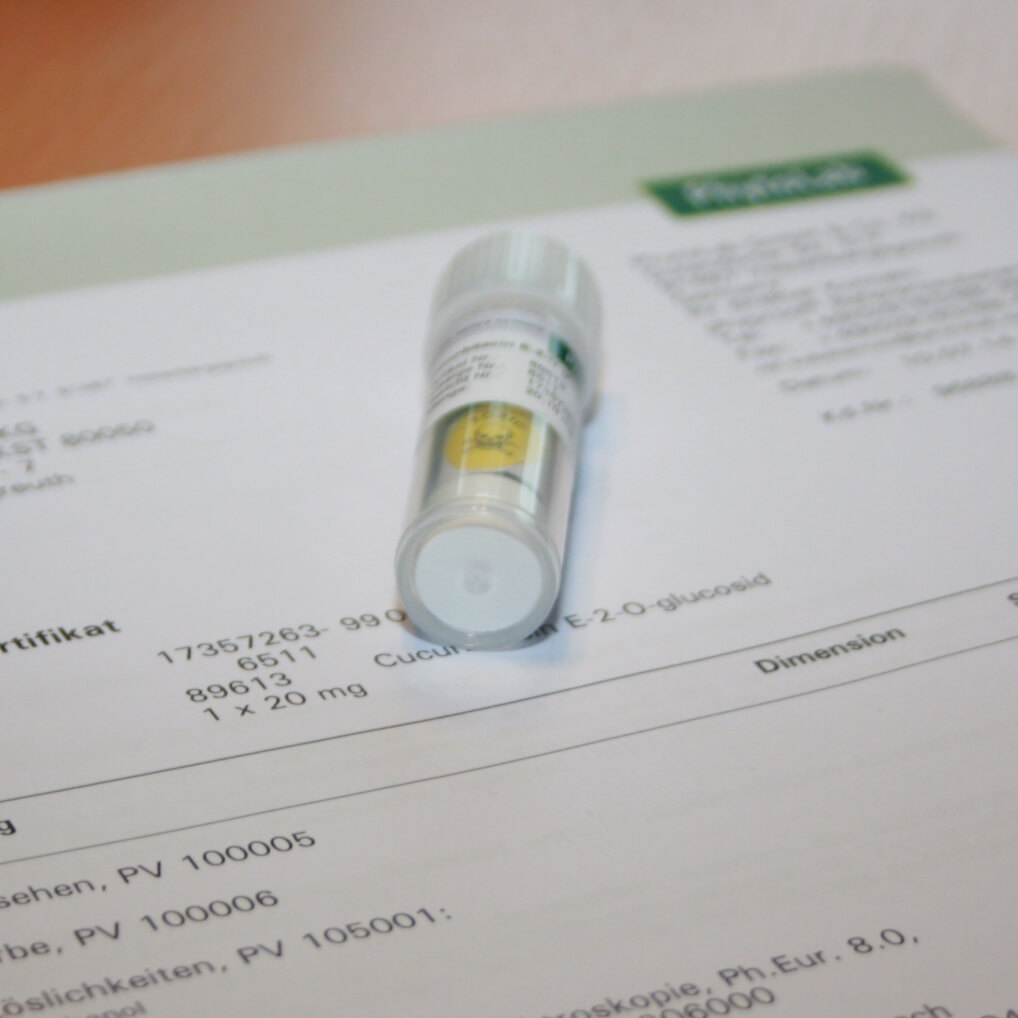

Lab analyses

Ensuring customers’ safety through extensive analyses

Each of our products is thoroughly analyzed following our internal requirements. PhytoLab, an independent, accredited laboratory for plant analysis, handles our verification checks. Affiliated with the nature network, PhytoLab is familiar with the variety of plants used by MartinBauer. With its decades of experience, this lab is a significant contributor to our product safety.

Our production process

Knowledge that has been tried and tested over decades paired with state-of-the-art technology

To us, technology has always been a way to chart a path towards a responsible future. When processing our botanicals, we use innovative and proven methods that protect all active and inactive ingredients.

Our environmentally friendly, natural, residue-free and safely applicable mabapex® disinfestation process has been around since 1986.

mabatherm® puts the heat on germs with superheated steam, our gentle germ reduction process for at risk-components

mabaselect® filters out foreign particles, using laser technology